High-Efficiency And Versatile Stile And Rail Wood Moulder

High-production Stile And Rail Moulder Machine

Consistent Products

Increased Throughput

Lower Labor Costs

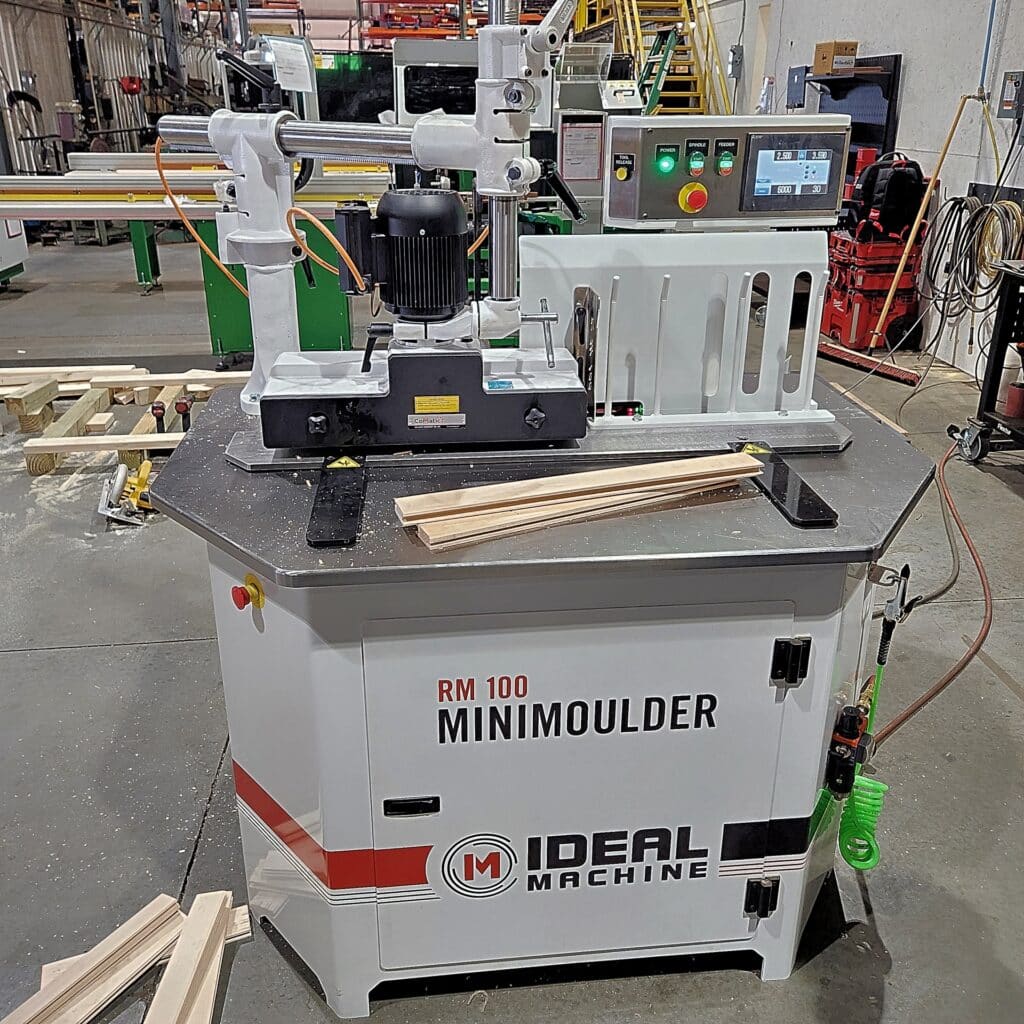

RM-100 MiniMoulder Stile And Rail Moulder From Ideal Machine

With the RM-100 from Ideal Machine, you can increase material production consistency and cut down on labor costs with our operator-friendly configurations. We offer multiple versions of the MiniMoulder to meet your specific needs. Features like our optional material hopper, touch screen controls, automated outer material fence, and more will make this machine an essential stile and rail moulder in your operation. Ask about our different available features when you submit your quote request to get the custom machine design that will best meet your needs.

RM-100 Stile And Rail Wood Moulder Specifications

- High-frequency Electric Spindle for smooth operation

- HSK interchangeable spindle, standard

- Digital readout for Z-axis spindle adjustment

- 8 HP at 12,000 RPM

- 230 volt or 480 volt

- Variable spindle RPM (Up to 12,000 RPM)

- Variable material feed speed: 20-60 Feet per minute

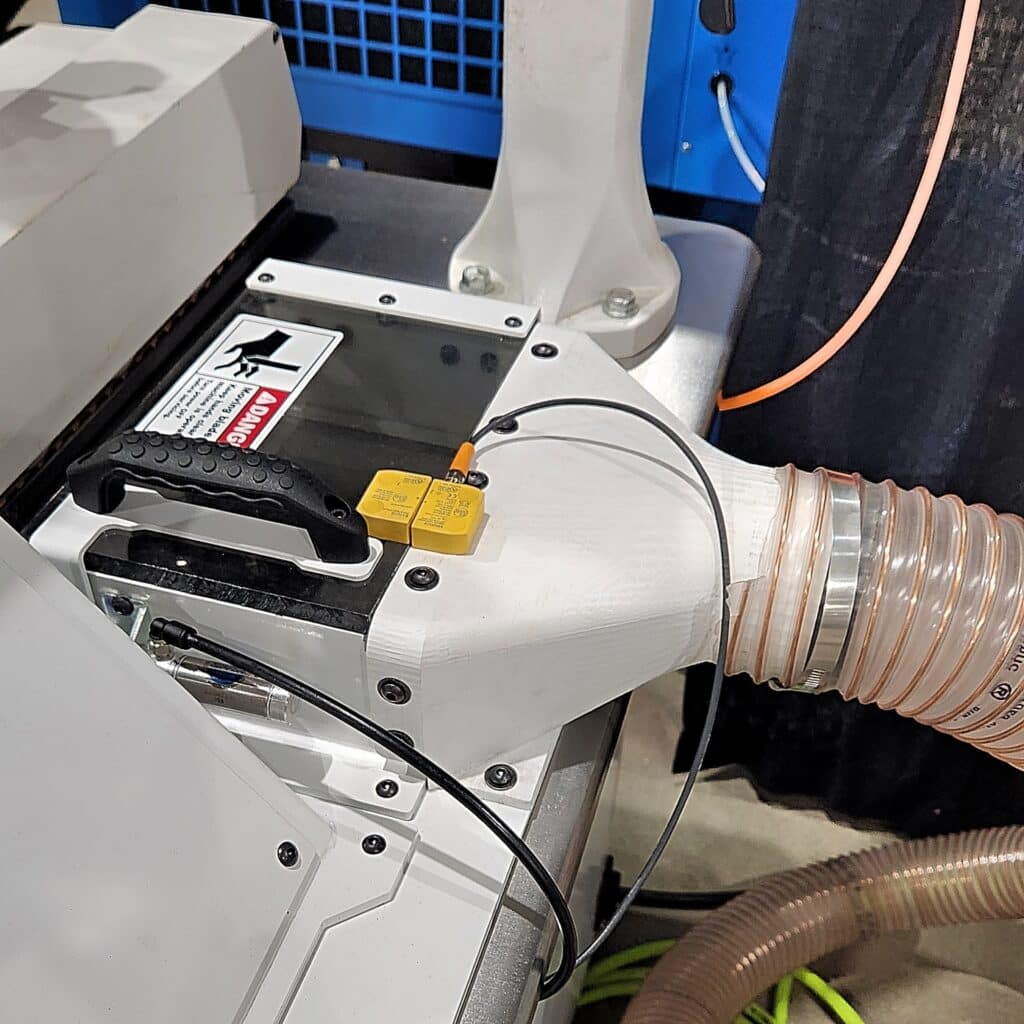

- Reversible cutter rotation for climb cutting (requires safety cage)

- Bore diameter determined by tool holders

- Hopper feeding, typically face down

- Digitally positioned outboard sizing fence

- Up to 20 preset “recipes“ for pre-programmed set-ups

- Part length max: none

- Part length min: 5”

- Part width max: 8-1/2”

- Part width min: 1-1/2”

- Tool diameter: 5" (up to 7" available upon request)

- Feed direction: Available in Right to Left or Left to Right (R-L is standard)

- Dust collection: 1x outlet at 4”

- Climb or conventional cutting

- Compressed air required: 80 PSI

RM-100 Stile And Rail Wood Moulder Available Options

- Hydraulic HSK interchangeable spindle

- Manual setting of sizing fence

- Digital readout for axial adjustment

- Higher HP Spindles up to 20 HP

RM-100 Hiland Model - No Hopper Feed Stile And Rail Wood Moulder

The Hiland Model RM-100 wood moulder is just like the other RM-100 stile and rail machines except it does not have an automatic hopper feed system. This makes it better for longer pieces of material. This is only one example of the many different options you have when choosing a wood moulder from Ideal Machine's RM-100 lineup.

RM-100XL Stile And Rail Wood Moulder With Extra Large Table Top

Meet the RM100-XL. This is the latest edition of the RM100 stile and rail machine to leave our shop. This version is set up with an extra large table top and spring-loaded material bumpers (just like the Hiland RM100) to accommodate wider material up to 18.5" wide depending on the size of your cutter head. Let us know if you need to shape and mold wider material, we can set you up with an industrial-grade large wood shaper for your larger parts.

Hopper Feed System

The RM-100 Hopper Feed System is a standard feature of this stile and rail machine. It makes batching material much easier. RM-100s can be ordered without the hopper.

Touch Screen Control

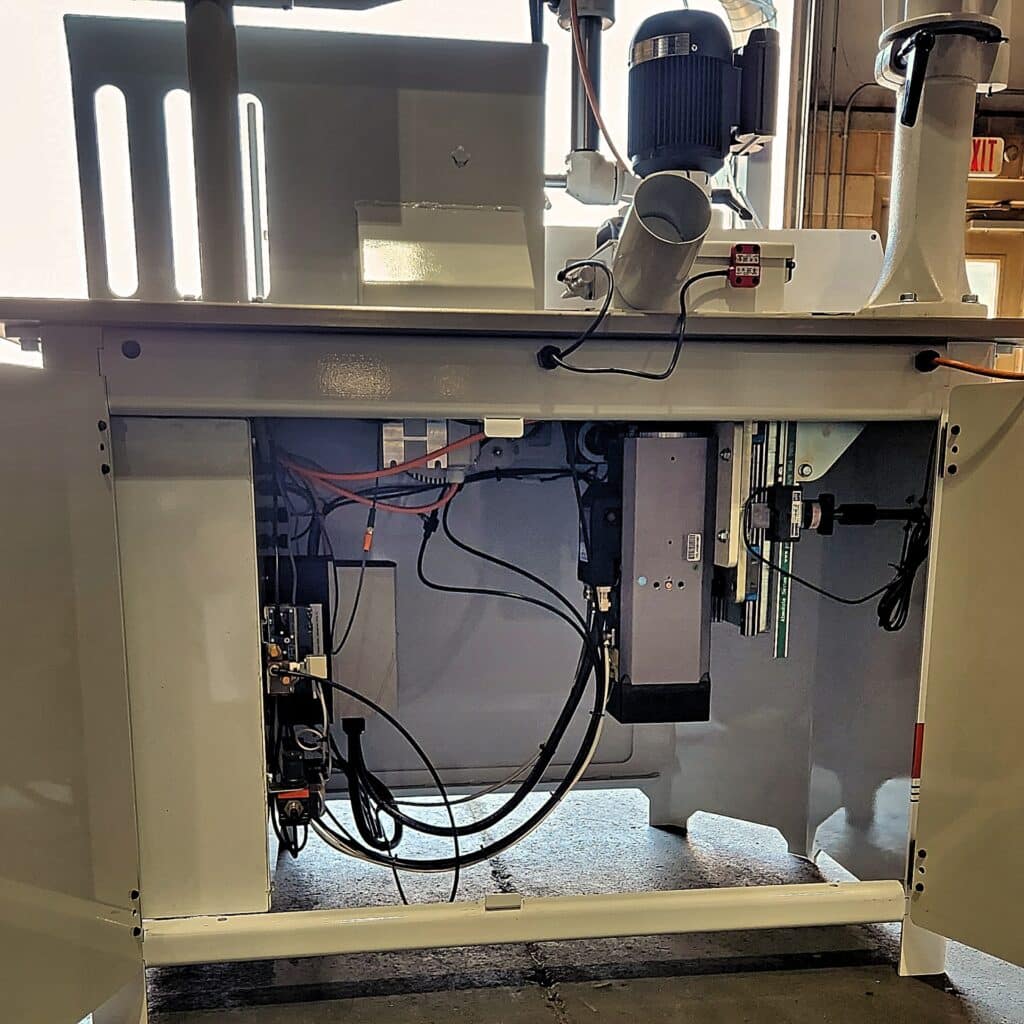

The RM-100 offers PLC touchscreen controls. Any operator will be able to quickly learn to use them. PLC controls are optional, manual stile and rail machines can be ordered.

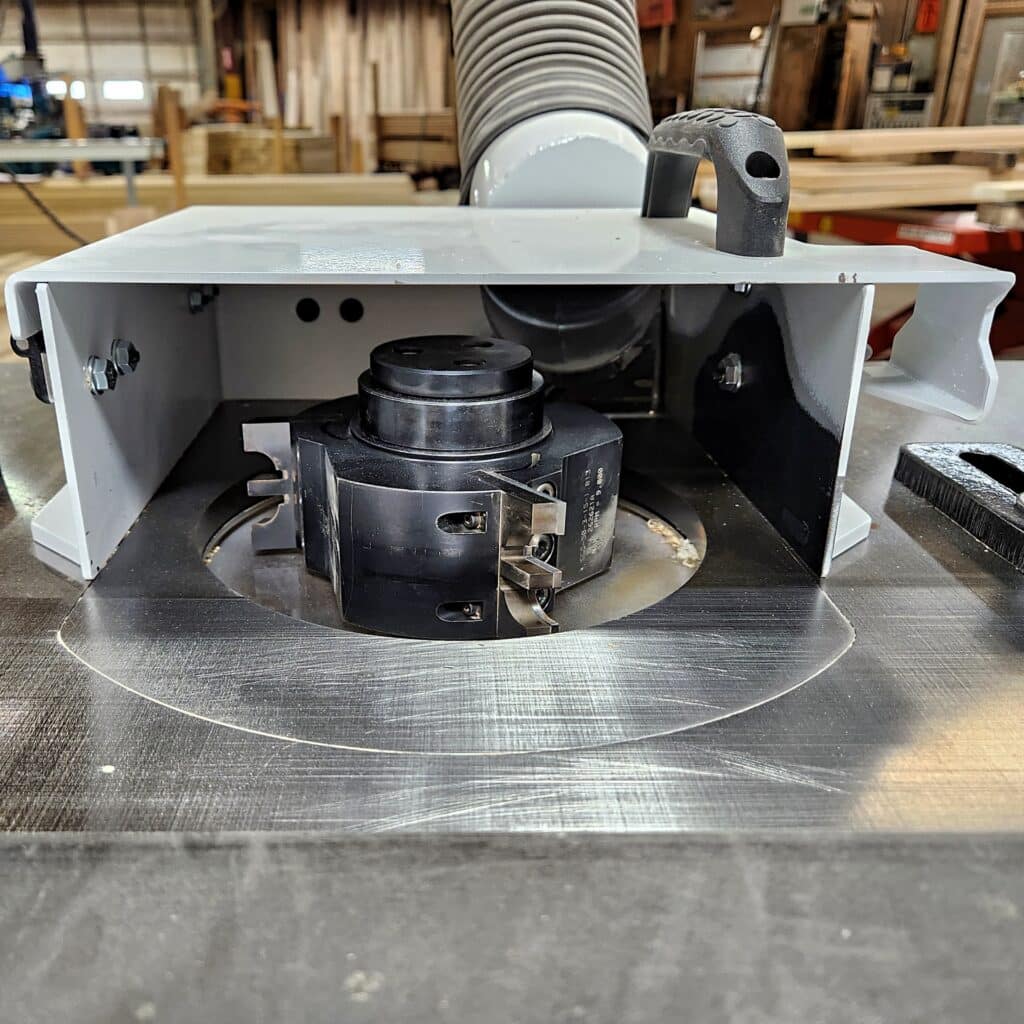

HSK Quick Change

HSK spindle cutter heads offer quick tool changing between jobs. This is just another way Ideal Machine's products are easy to use and increase your business's productivity.

Digital Material Fence

Use the PLC touchscreen controls to adjust your outboard material fence digitally for exact material widths every time. Faster setup and reduced operator error.

Consistent Precision Shaping

Take advantage of the high RPM HSK spindles to make consistent, precision cuts every time. Less material tear-out and smooth shaping will improve the quality of your part's production.

Some Of Our Satisfied Clients

We Make Versatile

Production Simple

Find A Dealer

Contact us for pricing and features.

Receive & Install

We ship the machinery with all the parts and instructions for fast setup.

Operate Efficiently

Enjoy increased workflow and consistent shaping in your shop!

Why Choose A Wood Moulder From Ideal Manufacturing?

Machinery is

guaranteed to work

as described

1-year warranty on our

parts and manufacturer’s

warranty on the rest

Quick setup

and

operation

We provide full

customer service

and support

Efficient Stile And Rail Shaping Equipment

Is your shop’s production and profits hurting from the following:

- Current stile and rail production is inconsistent

- Setup and operation is time-consuming

- Your shaping system is not versatile for your shop’s needs

We understand how using an inefficient shaping system makes product consistency difficult.

This is why we developed a versatile shaping machine designed to produce consistent stile and rail products.