Wood, Vinyl, and Aluminum Half-Lap Joint Cutter Machines

4 Industrial Half-Lap Joint Machines

Consistent Products

Increased Throughput

Lower Labor Costs

4 Half-Lap Joint Machine Models From Ideal Machine

In January of 2023, Ideal Machine purchased the inventory and the manufacturing rights of the Newport Machine lineup from Crestfield Machine, formerly Hermance Machine Company.

All 4 of the MH4 series machines are perfect for cutting Half Lap joints in wood, vinyl, and aluminum. These joints are most commonly used in SDL and TDL bars, window grills, and decorative cabinetry. Their general machinery specifications are all the same, the difference is that each unit offers one or two features that the unit before it in the lineup does not. These added features are all listed below. The difference in features do make a big difference from version to version. CLICK BELOW to watch some video footage of the MH4 Half-Lap Machines in action!

MH4 Half Lap Joint Machine

Manual Half Lap Model:

The operator must feed the material into the half-lap machine and trigger each cut type. It includes a 10ft solid infeed table with 4 manually adjustable stops.

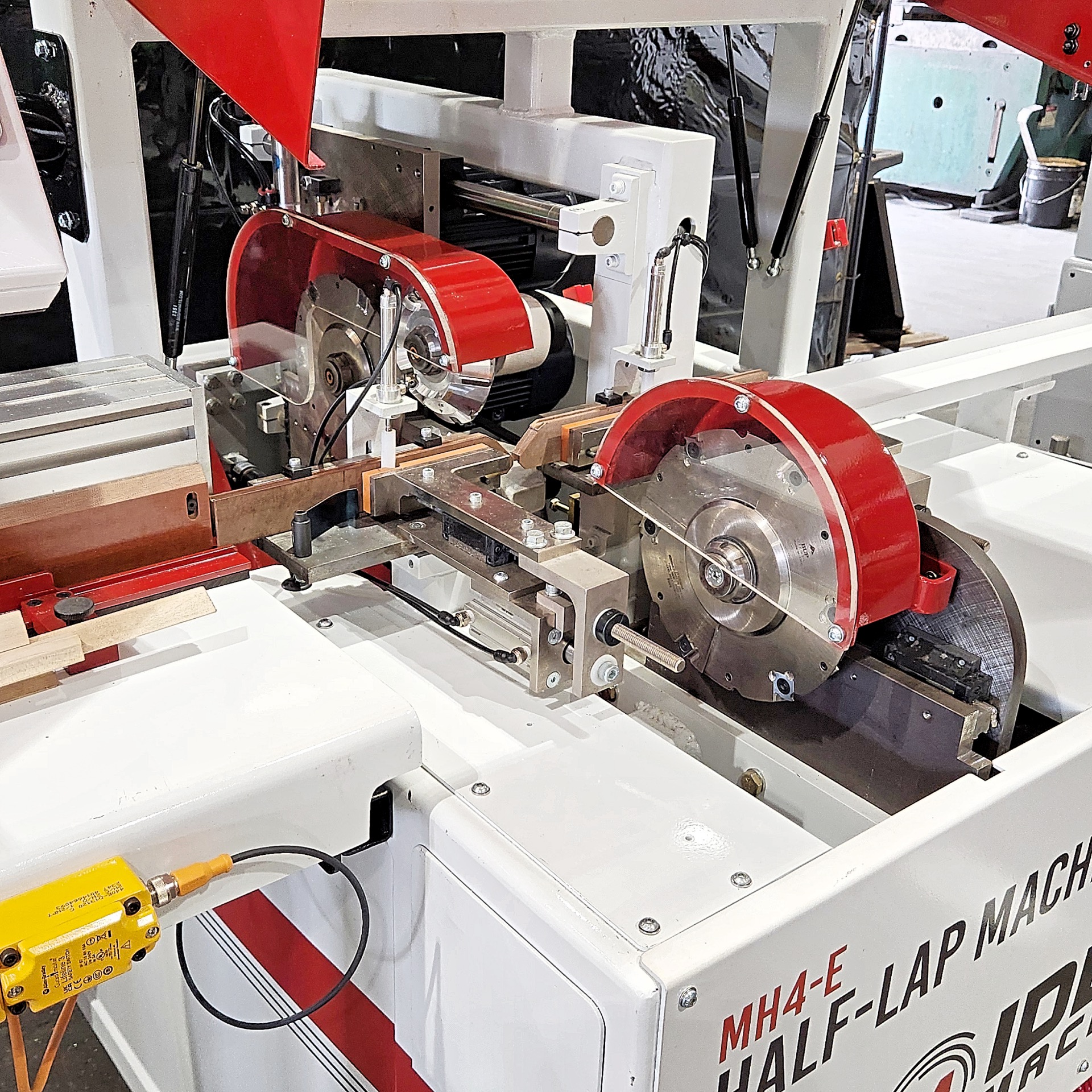

MH4-E Half Lap Joint Machine

8ft Automatic Material Pusher (Longer lengths available)

Window Grid Software

Touchscreen Setup

MH4-ES Half Lap Joint Machine

8ft Automatic Material Pusher (Longer lengths available)

Window Grid Software

Touchscreen Setup

+/- 60 Degree Cut-Off Saw

MH4-ESC Half Lap Joint Machine

8ft Automatic Material Pusher (Longer lengths available)

Window Grid Software

Touchscreen Setup

+/- 60 Degree Cut-Off Saw

End Coping Station

MH4 Series Half Lap Joint Machine Specifications

Motors: 3 @ 1.1Kw ea. (1.5HP ea.)

Voltage: 220-480 V

RPM: 6,200 RPM @ 60Hz

Air: 6 Bar (85 PSI)

Tooling: Insert Carbide

Profile Range: 1/4" to 1 1/2"

Dust Collection: 6” Diameter

Cycle Time: 4-6 Seconds

One Set of Tooling Included

Some Of Our Satisfied Clients

Ready To Cut Precision Lap Joints?

MH4 Half Lap Joint Machines

Find A Dealer

Contact us for pricing and features.

Receive & Install

We ship the machinery with all the parts and instructions for fast setup.

Operate Efficiently

Enjoy increased workflow and consistent shaping in your shop!

Why Choose An Ideal Machine Industrial Half Lap Cutter?

Ideal Machine is re-introducing the Newport Half-Lap Machines into the market. We are so excited to offer the MH4, MH4-E, MH4-ES, and MH4-ESC Half Lap Joint Machines to the woodworking industry. All 4 machines are now available under the Ideal Machine brand. If you are interested in an American-made Half-Lap Joint Cutting Machine then Ideal Machine’s Half-Lap Machines are what you’re looking for.

If you need a custom configuration or if you have questions about the functionality of the Half-Lap Machines simply fill out a quote request and indicate your interest in a Half-Lap or fill out a contact form and ask us your question. We are excited to offer these machines on the market and get them back in circulation after years of no availability.

Machinery is

guaranteed to work

as described

1-year warranty on our

parts and manufacturer’s

warranty on the rest

Quick setup

and

operation

We provide full

customer service

and support

The MH4-E Half-Lap Joint Cutting Machine

The MH4-E is the second machine in the Half-Lap series from Ideal. It is the first of the automatic half-lap machines available. It does not include the cut-off saw or the end coping station upgrades but it does allow for automatic material feeding and lap joint cutting.

The MH4-E is equipped with a programmable indexing material pusher. This feature makes the half-lap joint-cutting process fully automatic. Once your cut list distances and number of parts to be processed are entered into the machine, the material pusher increments the parts for the cut sequence. The MH4-E will continue to run until the batch is finished or the machine runs out of material. Entering the cut list is made simple thanks to the user-friendly touchscreen system and window grid software.